03.02.2019

03.02.2019Some of your favorite bacteria are domesticated

Just as in agriculture, domestication has usually been to the benefit of our taste buds.

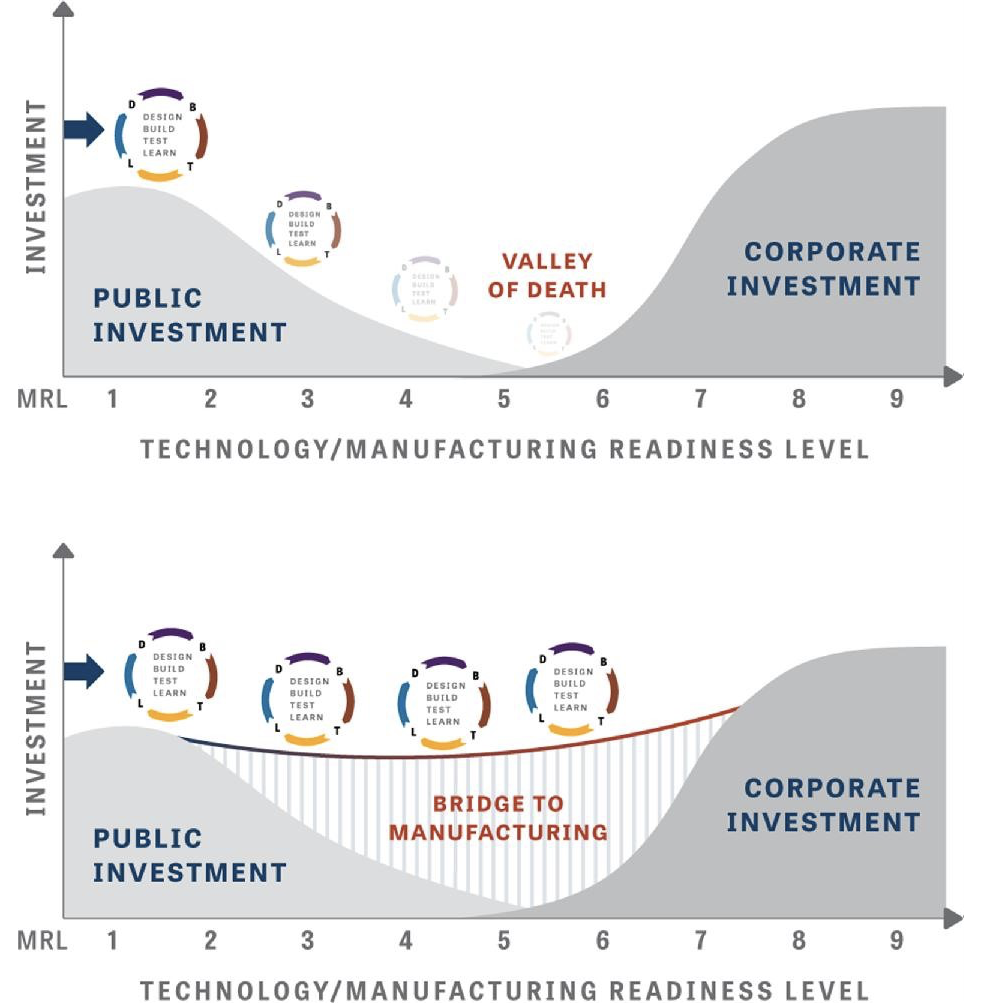

The bioeconomy holds enormous promise as a means to transform manufacturing into a more sustainable, circular system powered by renewable biology instead of fossil fuels. But taking a promising biotechnology innovation from initial discovery in the lab to full-scale commercialization is an arduous journey filled with risks, uncertainties, and challenges that can easily derail progress.

The manufacturing readiness level (MRL) framework provides a valuable roadmap for new biomanufacturing processes to systematically mitigate risks and reach maturity through crucial development stages. Each advancement along the scale from BioMRL 1 to BioMRL 10 represents years of intensive research, experimentation, iteration, and capital investment.1

Image source (1)

Image source (1)

At BioMRL 4, the initial proof-of-concept has been replicated and verified independently in strains and systems that closely mirror the realities of industrial production. The process has been proven out beyond just the first lab that discovered it. Critically, the process economics are rigorously assessed through Techno-Economic and Life Cycle Analyses. The projected costs and sustainability impacts are evaluated to determine if further investment and development look justified.

Achieving BioMRL 4 signifies a transition point where strategic partnerships must be forged between the innovator and pilot-scale manufacturer. The technology developer shares the details of the process, strains, and conditions with an industrial partner who can design and construct production-scale systems. The manufacturing partner takes charge of scale-up logistics while the developer continues innovating on next-generation improvements in parallel.

Significant time, money, and effort are required to properly execute the pre-competitive engineering, iteration, and analyses necessary to achieve this degree of manufacturing maturity. The payoff comes from rigorous de-risking - weeding out innovations with insurmountable challenges from those that demonstrate enough promise to warrant ongoing development.

A thoughtful stage-gate process creates a viable path to take a new technology from idea to impact. Newly created biotechnology ideas that once only sounded promising can now have a higher chance of success to exceed environmental and economic goals, positively impact society, and attract ongoing investment. By bridging the gap between laboratory discovery and manufacturing viability, reaching BioMRL 4 represents a watershed moment on the winding road to commercialization.

While there is much work ahead, we are excited to continue building our internal data tools and successfully bringing more microbes through this process to commercialization with our partners. Be sure to follow us on LinkedIn Here!

03.02.2019

03.02.2019Just as in agriculture, domestication has usually been to the benefit of our taste buds.

03.01.2019

03.01.2019Bioengineers have worked for thousands of years without the title, and there is no better proof of the success of that model than domestication.

02.16.2019

02.16.2019There is so much potential in microbiology, so many bacteria we could come to terms with, and not enough time to wait.